If you have any questions please contact us!

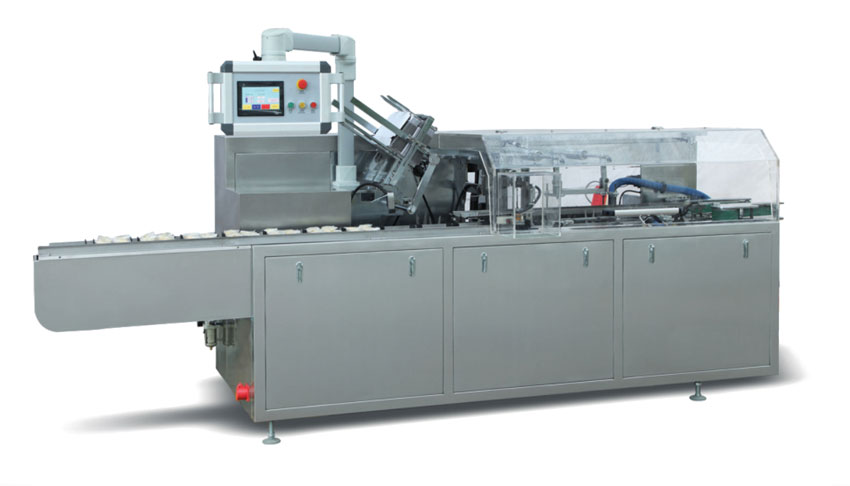

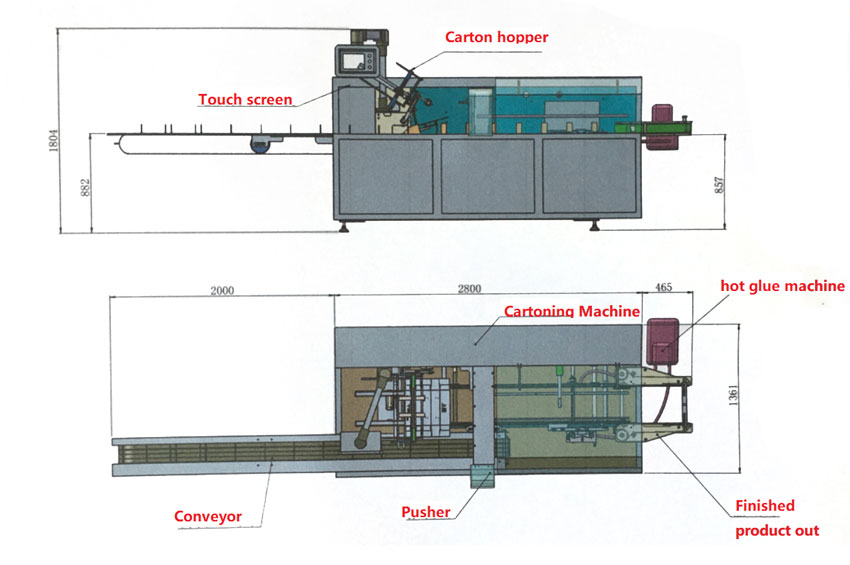

Dimensions in mm: 5265×1400×1804(L×W×H)

Weight in kg: 1200

Standard power supply: 380V / 50Hz three phase

Power consumption in KW: 1.5kw

Air consumption: 120-160L/min

Compressed Air Pressure: 0.5-0.8MPa

The work surface of the horizontal cartoning machine opens upward, and the boxes are moved horizontally for cartoning.

Horizontal cartoning machines are relatively more flexible and suitable for boxes of different sizes, and the workbench can be adjusted as needed.

Horizontal cartoning machines can adjust production capacity according to changes in the size of the workbench. At the same time, the horizontal cartoning machine can more easily realize automated production, and ensure production efficiency and quality through computer control and monitoring systems.

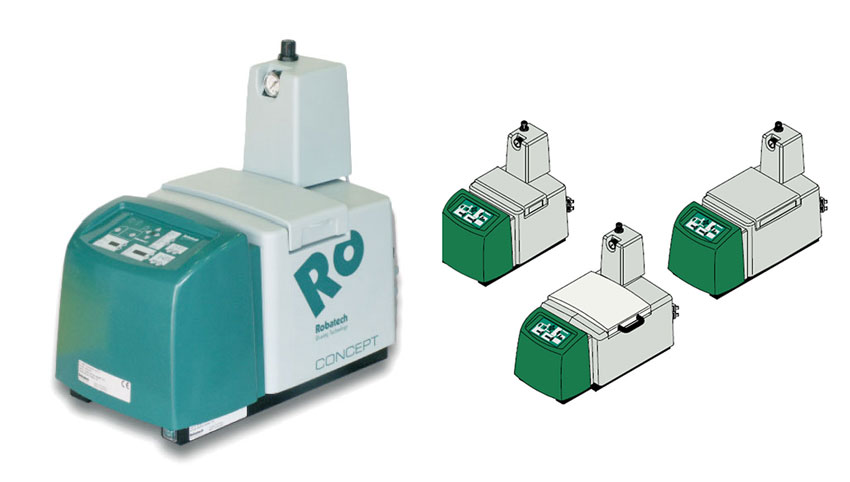

YL-40 Horizontal Automatic Cartoner is high technology product incorporates of pneumatic-photo-electro-mechanic. It is suitable for inserting tissue, pillow wrapped products, pharmaceutical products and food similar package into carton in a range. The machine finishes running by a series of photo-electro controller to make the machine stability and guarantee the packing quality. It includes canton suction and open, products put into, printing batch number, sealing carton with tuck-in or hot melt glue device.

Weight & Dimensions

|

Type |

YL-40 |

|

Dimensions in mm |

5265×1400×1804(L×W×H) |

|

Weight in kg |

1200 |

Output & Speed

|

Steady production speed |

30-40cartons/min |

Carton

|

Grammage |

Between (350-400)g/m2 |

|

|

Item |

Pouch Size mm |

Carton size mm |

|

1 |

|

(100-250)*(180-230)*(25-90) |

Utilities

|

Standard power supply |

380V / 50Hz three phase |

|

Power consumption in KW |

1.5kw |

|

Air consumption |

120-160L/min |

|

Compressed Air Pressure |

0.5-0.8MPa |

|

Noise |

<80 dB |

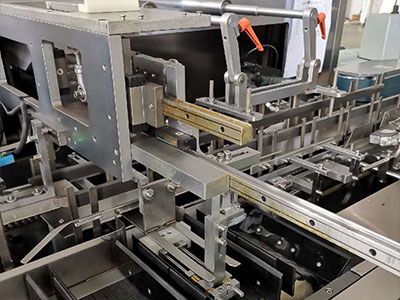

The cartoning machine includes an automatic station to form the cartons. The carton boxes are held by vacuum. The suck carton device use opposite pull carton which make carton suck very steady

No suction carton by missing product

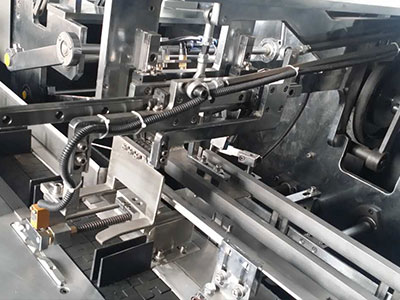

Product will be manually loaded on conveyer by manual, then other things finished automatically.

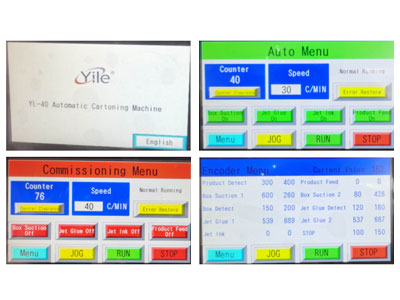

Automatically displaying device for trouble, speed and finished products counting

Machine stop running if no products or incorrect position of products. And stop automatically if incorrect position of product into carton after return

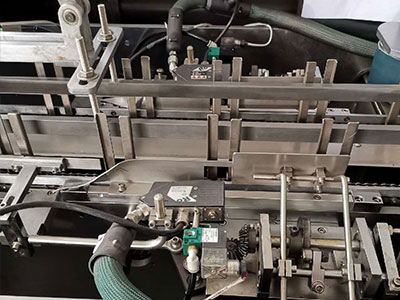

Adopt human-machine operation system.

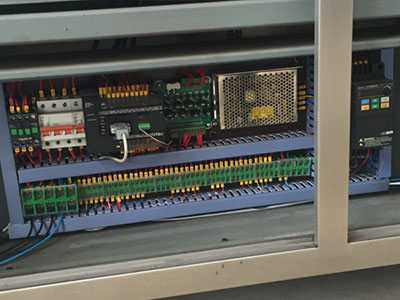

International famous brand of electric components such for PLC touch screen, frequency inverters, etc

Stable performance, operation is easy Controls

Product presence detection sensor

Carton present detection sensor

|

|

|

| Feeding product on conveyor by manual | Feeding product on conveyor by manual | Carton suck device |

|

|

|

| Carton opposite pulling device | carton double suck plate | Carton hopper |

|

|

|

| Pusher | Pusher | Carton sealing by glue |

|

|

|

| finish cartons come out by carton transport belt | Touch screen | Big cover |

|

|

|

| Electrical circuit | Touch screen | Touch screen |

Technical Data

Yile is a cartoning machine manufacturer and supplier, factory provides you Automatic Case Packing Machine, Cartoner Machine, Box Packing Machine, Carton Packing Machine, Automatic Cartoning Machine, Food Cartoning Machine, Pharmaceutical Cartoning Machine, Case Packer Machine related knowledge, including speed, price, working principle, function, correct use Methods, and other news.

Corrugated boxes offer stronger protection for shipping, while cardboard boxes suit lightweight retail pa...

In the competitive landscape of modern business, product packaging is far more than just a container to h...

GET A QUOTE

+86 13566127969

If you have any questions please contact us!