If you have any questions please contact us!

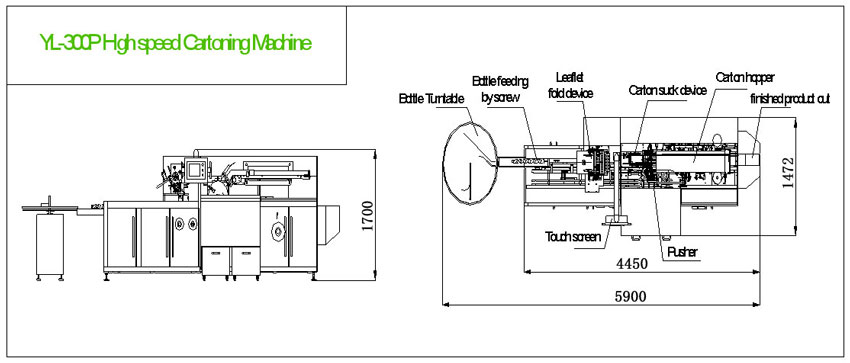

Dimensions in mm: 4450×1460×1700(L×W×H)

Weight in kg: 2500

Steady production speed: 200cartons/min

Standard power supply: 380V – 50Hz

Power consumption in KW: 5.2 KW

YL-300P High speed cartoning machine can fold leaflet, open box, insert blister into box, emboss batch number and close box automatically.The highest speed can up to 260 boxes/min.

High speed cartoning machine is suitable for packing blisters, tubes, ampoules and other related objects into boxes intermittently. With advantages of wide range of application, high efficiency, stable running and is multi-usage. It can apply to packing medicine, food and toiletry.

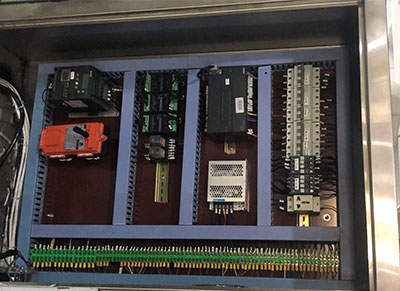

It adopts frequency inverter to adjust speed, human machine interface to operate, PLC to control, and photoelectric to supervise and control each station. So that once something unexpected happens during its running, it will stop and display the reasons automatically, which can solve the troubles in time. This machine can be used separately, and also can be linked to other machine to be a production line. Note: this machine can also equip hot melt glue device to do hot melt glue sealing for box.

Weight & Dimensions

|

Type |

YL-300P |

|

Dimensions in mm |

4450×1460×1700(L×W×H) |

|

Weight in kg |

2500 |

Output & Speed

|

Steady production speed |

200cartons/min |

Unfold Leaflets(optional )

|

Grammage |

Between( 60-70)g/m2 |

|

Size range |

(80-250) ×(90-170)mm (L×W) We suggested leaflet size :120*100mm |

|

Fold range |

(1-4 )fold |

|

Notice: The leaflet can be folded by the machine |

|

Carton and blister

|

Grammage |

Between( 250-350)g/m2 |

|

|

Item |

Bottle size mm |

Carton Size mm |

|

10ML |

|

90*46*35 |

|

20ML |

|

72*35*35 |

Utilities

|

Standard power supply |

380V – 50Hz |

|

Power consumption in KW |

5.2 KW |

|

Air consumption |

20m3/h |

|

Compressed Air Pressure |

0.5-0.7MPa |

|

Noise |

<70 dB |

1. YL-300P high speed cartoning machine can fold leaflet, open box, insert blister into box, emboss batch number and close box automatically.

2. It adopts PLC to control, and photoelectric to supervise and control each station. So that once something unexpected happens during its running, it will stop and display the reasons automatically, which can solve the troubles in time.

3. There are main driving motor and clutch brake inside the rack, and torque overload protector for each part of the transmission system on the machine board, which can separate the main driving motor and each part of transmission when it is in the case of overload, so that ensure the safety of the machine.

4. The machine is equipped with eliminating device. Leaflet, medicine plate and box will be detected by sensor before, and then product be exported after embossing batch number and closing box. The waste (no medicine plate or leaflet) will be found during detection process and removed at the outlet, so that ensure product quality fully meet the eligibility requirements.

5.The machine is continuous cartoner, which is more stable and faster than traditional intermittent cartoner.

6. The pusher way of machine is continuous slowly pushing, ensuring product is not damaged during the process of insertion.

7.This machine can be used separately, and also can be linked with other machine to be a production line.

Structure about every assembly unit

|

|

|

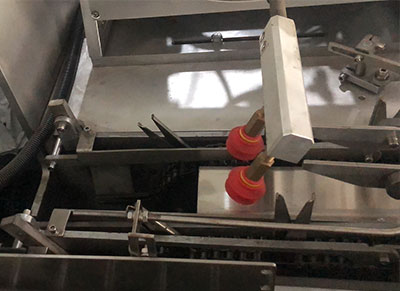

| Cochlea screw feeding system for bottle | Bottle positioning inside the buckets of cartoner | Detection sensor (no bottle,no suck carton) |

|

|

|

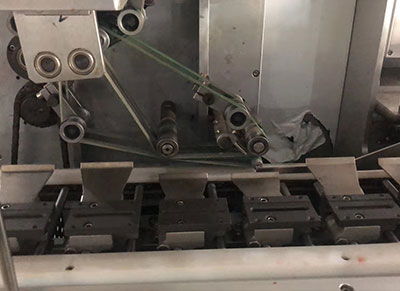

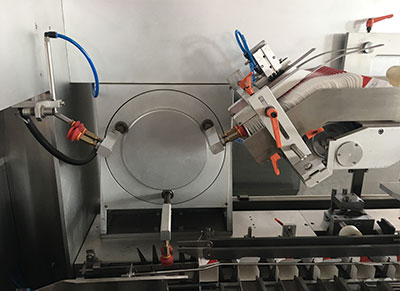

| Leaflet folding device | leaflet transport | Suck carton device |

|

|

|

| Carton hopper | Carton transport hopper | End carton sucker |

|

|

|

| Continuous pusher | Insert with leaflet | Carton transport chain |

|

|

|

| Touch screen | Electrical circle |

Whole Machine Picture

Technical Data

Yile is a cartoning machine manufacturer and supplier, factory provides you Automatic Case Packing Machine, Cartoner Machine, Box Packing Machine, Carton Packing Machine, Automatic Cartoning Machine, Food Cartoning Machine, Pharmaceutical Cartoning Machine, Case Packer Machine related knowledge, including speed, price, working principle, function, correct use Methods, and other news.

Carton boxes are indispensable in global logistics, protecting everything from groceries to electronics. ...

GET A QUOTE

+86 13566127969

If you have any questions please contact us!