If you have any questions please contact us!

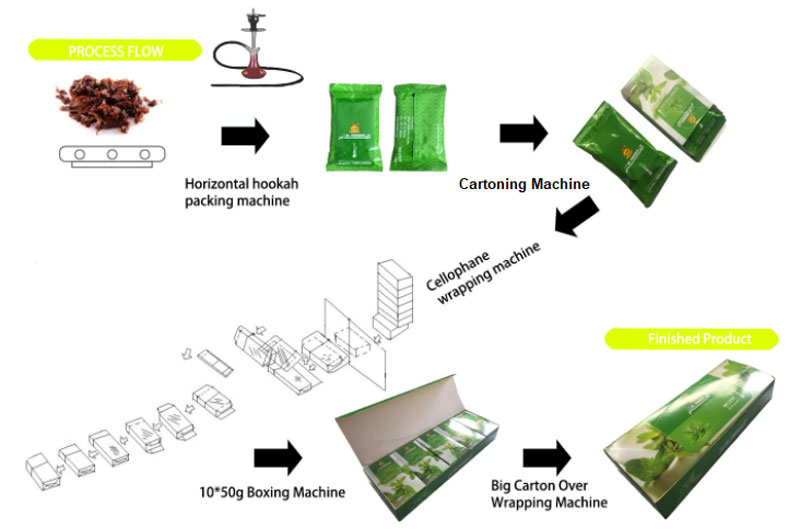

Offer of whole production line for Molasses sachet

Instruction

Suitable for water fume products in the Middle East.

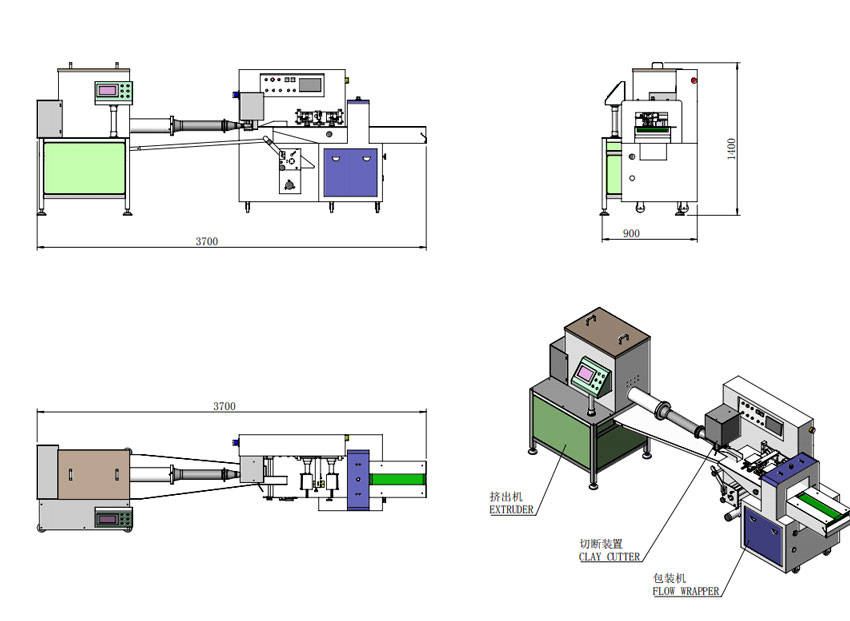

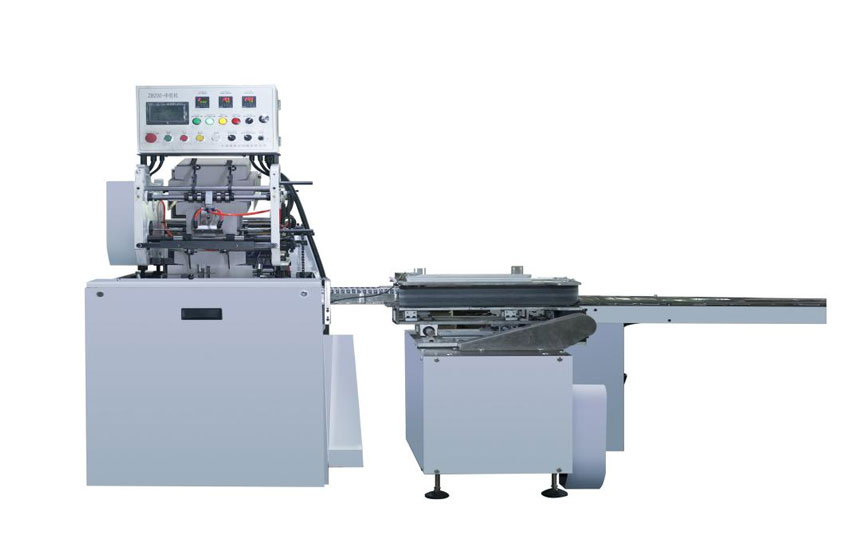

Machine Drawing Drawing

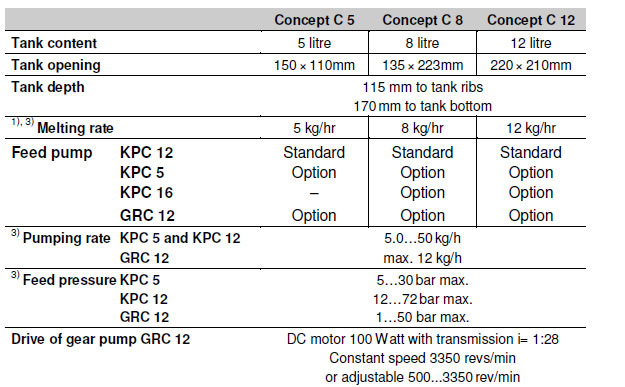

Technical Data

|

Model |

YL-350(Dual frequency conversion) |

|

Width of film |

≤250mm ≤350mm |

|

Extruder Type |

Single screw diameter |

|

InnerΦ123MM-outsideΦ133MM |

|

|

Mold range |

32*15(25g) 44*18MM(50g) 58*26(100g) 75*30MM(250g) |

|

Thickness of film |

25-70um |

|

Dimension of film roll |

Outer diameter:Φ ≤300mm |

|

Inner diameter: ≤ Φ75mm |

|

|

Packaging weight |

≤250mm(20-100g) |

|

Double Knife≤250mm |

Bag size: (65-145)*(30-90)*(3-30) mm (L*W*H) |

|

Double Knife≤350mm |

Bag size: (80-160)*(30-150)*(3-45) mm (L*W*H) |

|

Speed |

30-120 bags/min |

|

Power |

220V,50/60HZ, 4.7KW |

|

Outer dimensions |

3700*900*1400MM(L*W*H) |

|

Gross weight |

800kg |

|

Package size |

①2400*960*1600MM ②1880*790*1600MM(250X) |

Functions and Options

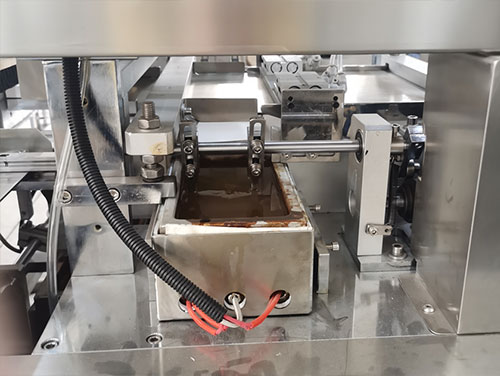

1. Extruder: double servo control, independent servo cutting, precise feeding.

2. The extruder adopts RV gearbox, and each output and input shaft is sealed by sealing ring.

3. The extruder adopts independent man-machine interface and PLC control system.

4. The structure of material hopper, screw and barrel adopts integrated 304 stainless steel welding process, which is simple and easy to clean (316 stainless steel material can be customized).

5. The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

6. The machine can independently complete automatic extrusion, metering, cutting, packaging, counting.

7. The whole set of equipment rack can be customized if all stainless steel materials and other specifications are required.

8. Packaging machine: adopt double frequency conversion control system, the bag length can be set as soon as cutting, no need to adjust the empty walk, one step in place, saving time and film. (three servo system can be customized if needed).

9. High sensitivity photoelectric eye color mark tracking, digital input sealing position, making sealing position more accurate.

10. Temperature independent PID control, better suitable for all kinds of packaging film materials.

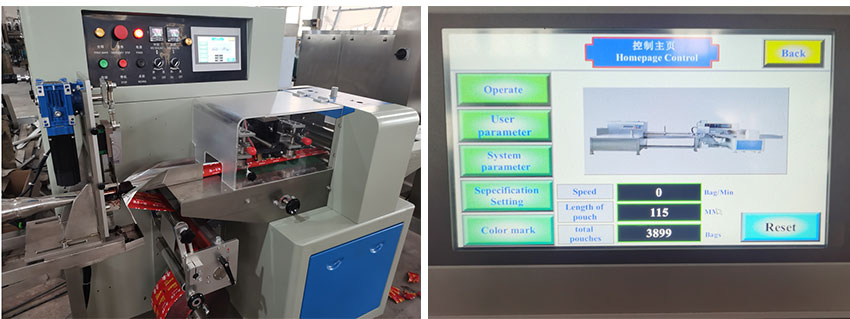

Machine picture

Instruction

Whole Production Line For Molasses Sachet is mainly used in automatic assembly line on the product itself quality detection and classification, also can be used in checking the packaging lack of examples or not. Also can replace manual weighing, in order to improve production efficiency and weighing the consistency and reliability. Widely used in food, medicine, cosmetic, industrial manufacturing, printing, logistics and other industries.

Specifications

|

Model |

YL-150 |

|

Weighing Capacity |

5g~500g |

|

Weighing Accuracy |

±0.3—0.5g |

|

Minimum Scale |

0.1g |

|

Weighing Scale Size |

400mm(L)x150mm(W) |

|

Weigh Sensor |

Double-beam load cell |

|

Conveying |

Food Belt(Belt Width:150mm) |

|

Display |

Chinese/English |

|

Machine Size |

L x W x H 1100mm x 700mm x1420mm The height from conveyor belt to the ground : 750+100mm |

|

Machine Weight |

Appr.80kg |

|

Power Supply |

Single-Phase AC220V |

|

IP rating |

IP54 standard |

|

Construction |

304SUS, Polishing |

|

Reject Method |

Air/Pusher Rejection System |

Functions and Options

●Strong stainless steel structure; Water proof design.

●High precision digital load cell;adopt high-speed digital filtering procesing technology; Automatic zero tracking

●Automatic belt speed adjustment according to different product choice

●Self-learning function of the product physical property

●40 products preset;easy to edit and recall(storage)

●Quickly product shift and speed recall

●Touch screen; friendly operation interface

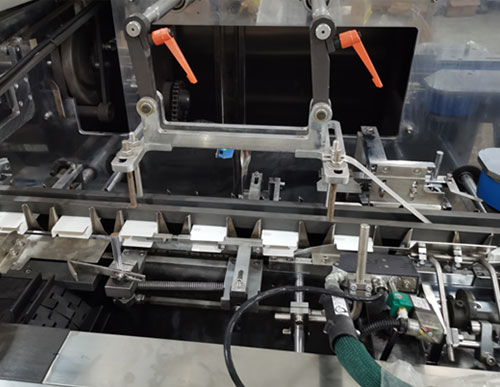

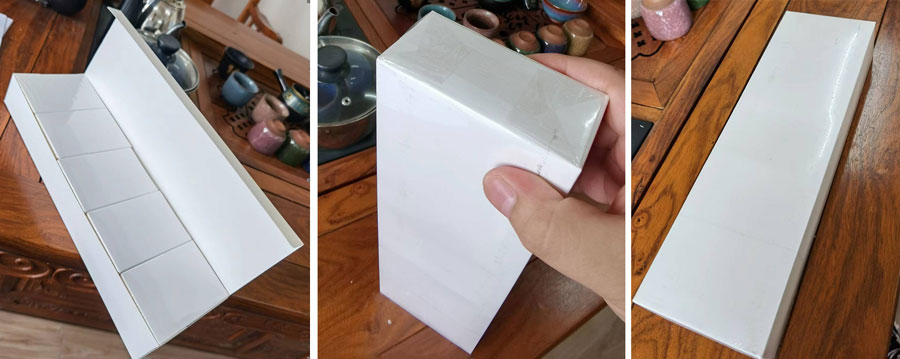

Cartoning machine and cellophane machine for single carton

Instruction

This equipment is new model developping base on integrated domestic and foreign vanguard technology .It is high technology product incorporates pneumatic-photo-electro-mechanic which improve by a large on performance of equipment and working efficiency, realize encasing fast, keep running steady and reliable when fast running.

This machine is suitable for automatic feeding round bottle / square bottle into carton which bottle use in pharmaceutical, cosmetic, food, health product. On line bottle unscramble and feeding, leaflet fold(1-4folds) and feeding, leaflet detecting, canton opening and forming, products and leaflet pushing into carton, printing batch number, sealing carton with tuck-in or hot melt glue device. Automatically reject lacking of leaflet or product and finished product out.

Machine frame adopt super stainless steel.

Sample picture

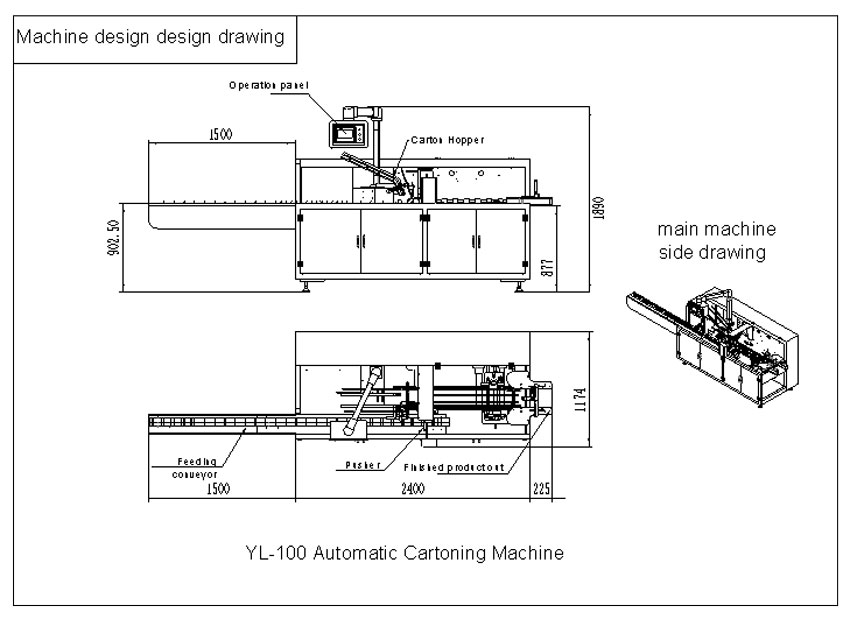

Technical Data

Weight & Dimensions

|

Type |

YL-100B |

|

Dimensions in mm |

3900mm×1100mm×1900mm (L×W×H) |

|

Weight in kg |

1500 |

Output & Speed

|

Steady production speed |

60cartons/min |

Carton and tube

|

Grammage |

Between(250-350)g/m2 |

|

|

Item |

Product size mm |

Carton Size mm |

|

I sachet into one carton |

|

90*58*20 |

Utilities

|

Standard power supply |

380V – 50Hz three phase |

|

Power consumption in KW |

1.5KW |

|

Air consumption |

20M3/h |

|

Compressed Air Pressure |

0.6MPa |

|

Noise |

<70 dB |

Functions and Options

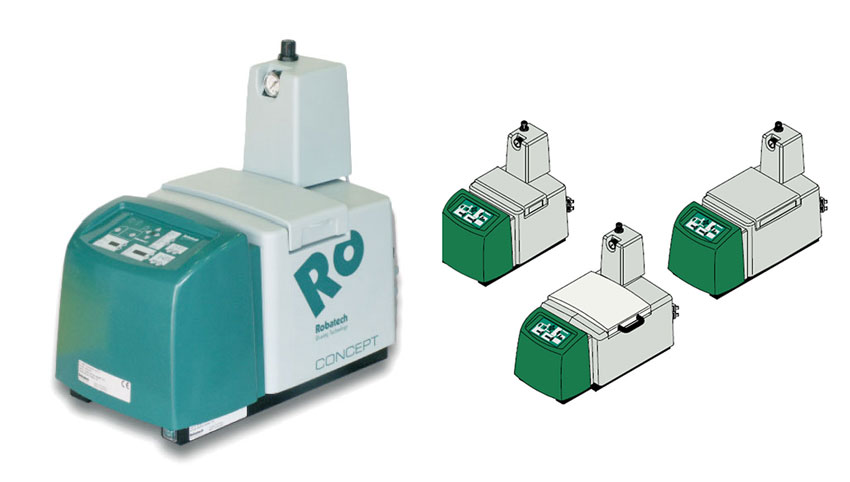

The cartoning machine includes an automatic station to form the cartons. The carton boxes are held by vacuum

No suction carton by missing product

Product will be manually loaded on conveyer by manual ,then other things finished automaticlly.

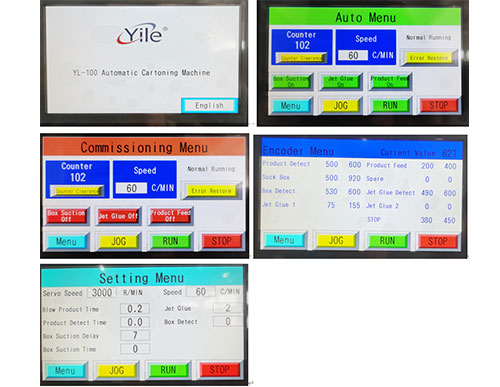

Automatically displaying device for trouble, speed and finished products counting

Machine stop running if no products or incorrect position of products. And stop automatically if incorrect position of product into carton after return or no cartons

Adopt human-machine operation system.

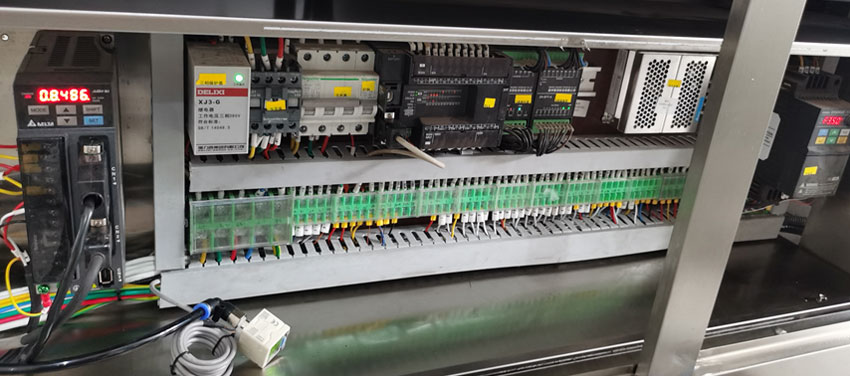

International famous brand of electric components such for PLC touch screen, frequency inverters, etc

Stable performance, operation is easy Controls

Sensors

Product presence detection sensor

Carton present detection sensor

Structure About Every Assembly Unit

|

|

| Carton magazine which can full of 400-500pcs cartons | Pusher (which product into carton) |

|

|

| Sensor for detect product | Carton sealing |

|

|

| PLC and electrical circuit | |

|

|

| Touch screen | |

|

|

| Power supply and vacuum air supply | Touch screen |

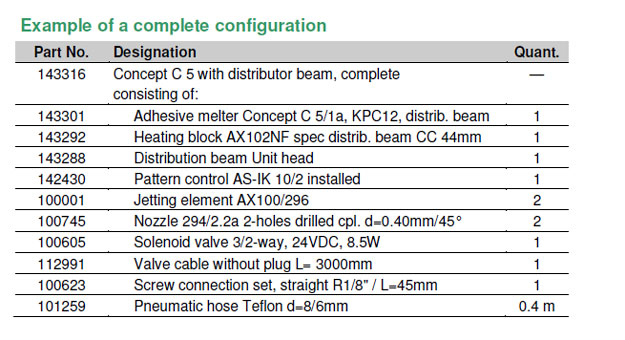

Technical Data

Instruction

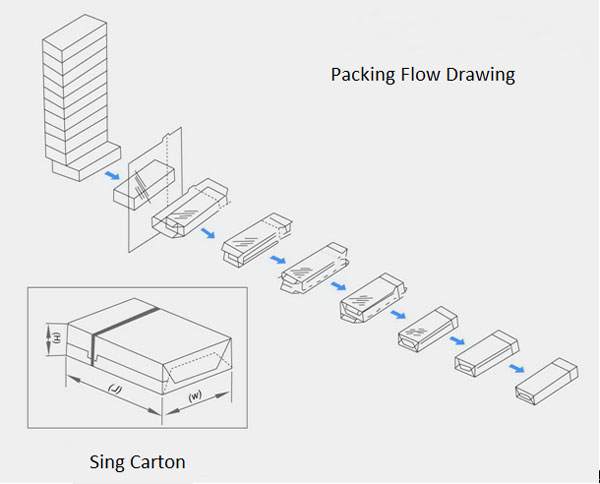

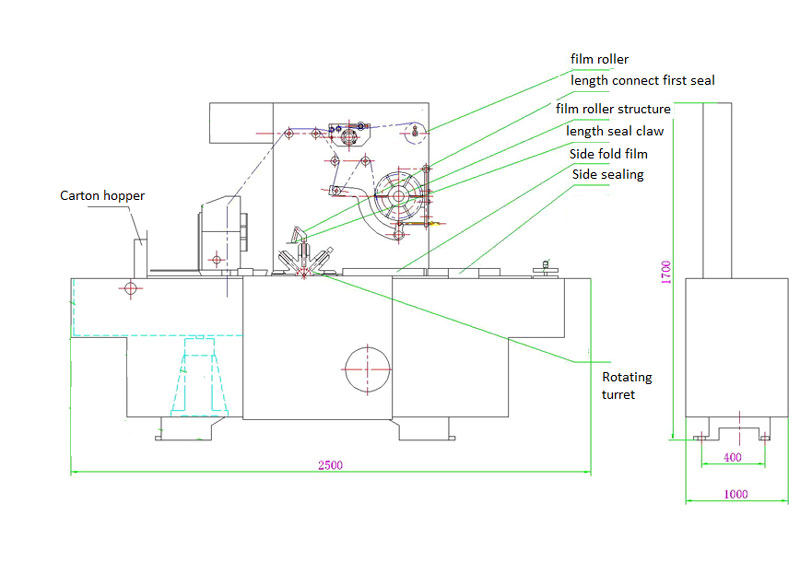

Automatic Cellophane Wrapping Machine, which is mainly applied to the outside decoration packaging of square-shaped box-packaged things of such industries as medicine, food, daily chemistry, cosmetics, video products rubbers, IT etc. For example, the medical box, chewing gum, healthy products, tea-leaf, cubic sugar, condom, eraser, mosquito-repellent incense, cigarette, tape, VCD (CD)disk, poker, soap, square-shaped battery and floppy disk etc. It has the function of anti-moisture and anti-falsification, and also enhances the product level and additional value. It can combine the box-packaged machine and code-spraying machine to manufacture.

Technical Data

|

Main technical parameters |

|

|

Package material |

BOPP film and gold tear tape |

|

Speed |

60packs/min |

|

Product size mm |

90*60*20m |

|

Power of supply |

AC220V 50Hz, 6.5Kw (single phase) |

|

Weight |

600kg |

|

Power consumption in KW |

5kw |

|

Outline dimensions (Lx W x H) |

(L)3000×(W)800×(H)1500mm |

|

Control system |

Button control |

Functions and Options

1. No need to regulate the height of two work tops of the machine when the mold is replaced, no need to assemble or dismantle the material discharge chains and discharge hopper. Reduce the replacement time of the mold four hours to the present 30 minutes.

2. New-type double safeguard mechanisms are used; hence other spare parts will not be damaged when the machine runs out of step without the stop of the machine.

3. Original unilateral hand swing device to prevent from shaking the machine adversely and the non-rotation of the hand wheel during the running of the machine can secure the security of the operator.

4. New-type double-rotary film cutting cutter can ensure no need to mill the blade during many-year use of the machine, which overcomes the defect that the traditional stationary single-rotary film cutting cutter was easily worn.

On the basis of the model YL-300A, this machine is a lengthened machine for the requirement of the packaging of bulk articles required by some users. This machine features by rational structure, good-looking in excellent taste, stable run, convenient in adjustment, the added photoelectric deviation pattern rectifying register system allows the packaging of printed film packing products such as soaps and paper towel.

Packing Flowing Drawing

Machine Design Drawing

Feature

1. It adopts the automatic feeding way, the structure is compact and reasonable, and the operation and adjustment is very simple;

2, It use touch screen, PLC programmable control system, man-machine interface display make the operation more clear and simple, it’s high automation and more humane;

3, It use photoelectric sensor to detect automatically,if there is no product,it won’t suck down the box,so it can save packing material;

4, It can use protect cover according to customer requirement, easy to operate, and beautiful appearance.

Main Technical Parameter

|

S/No. |

YL-300 |

|

Packing Speed |

10-22boxes/min |

|

Box dimension |

Customize according to client’s box |

|

Paper quality |

250-300g/m2 |

|

Motor power |

1.3KW |

|

Power supply |

380V 50Hz |

|

Machine noise |

≤80dB |

|

Air supply |

0.5-0.8 Mpa |

|

Air consumption |

120-160L/min |

|

Machine weight |

600Kg |

Machine picture

|

|

|

|

|

|

Instruction

This machine is widely used in the packaging of various single-piece large-box items or multiple small-box items (with gold cord) in the industries of medicines, health products, food, cosmetics, stationery, audio and video products.

Performance characteristics

The work of the machine is completed by a series of servo motors inside the machine to drive various connecting rods and components. It adopts multi-function digital display frequency conversion stepless speed regulation, PLC programming control technology, automatic box feeding, automatic counting, and touch display realization. Man-machine interface, pneumatic drop film; and can be used in conjunction with other production lines

Technical Data

|

Main technical parameters |

|

|

Package material |

BOPP smoke film and gold cable |

|

Speed |

10-15packs/min |

|

Product size mm |

(L)100-360×(W)50-230×(H)25-130mm 300*90*40mm |

|

Power of supply |

AC220V 50Hz, (single phase) |

|

Weight |

850kg |

|

Power consumption in KW |

6kw |

|

Outline dimensions (Lx W x H) |

(L)2320×(W)980×(H)1830mm |

Yile is a cartoning machine manufacturer and supplier, factory provides you Automatic Case Packing Machine, Cartoner Machine, Box Packing Machine, Carton Packing Machine, Automatic Cartoning Machine, Food Cartoning Machine, Pharmaceutical Cartoning Machine, Case Packer Machine related knowledge, including speed, price, working principle, function, correct use Methods, and other news.

Carton boxes are indispensable in global logistics, protecting everything from groceries to electronics. ...

GET A QUOTE

+86 13566127969

If you have any questions please contact us!