If you have any questions please contact us!

Type: YL-100B

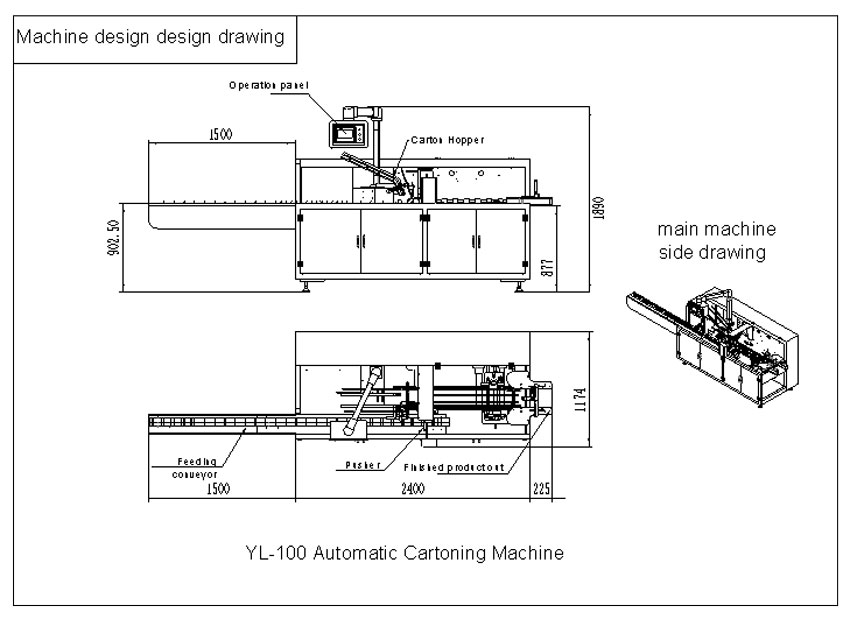

Dimensions in mm: 3900mm×1100mm×1900mm (L×W×H)

Weight in kg: 1500

Grammage: Between(250-350)g/m2

Standard power supply: 380V – 50Hz three phase

Power consumption in KW: 1.5KW

Air consumption: 20M3/h

Instruction

YL-100B Cartoning Machine With Hot Glue Machine Link To Cellophane Wrapping Machine For Molasses Sachet for molasses sachet packaging is a food packaging machine production line. It is a highly integrated automation equipment suitable for packaging medicines into cartons

This machine is suitable for automatic feeding round bottle / square bottle into carton which bottle use in pharmaceutical, cosmetic, food, health product. On line bottle unscramble and feeding, leaflet fold(1-4folds) and feeding, leaflet detecting, canton opening and forming, products and leaflet pushing into carton, printing batch number, sealing carton with tuck-in or hot melt glue device. Automatically reject lacking of leaflet or product and finished product out.

Machine frame adopt super stainless steel

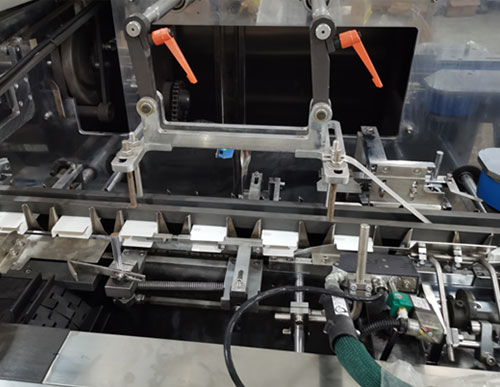

Sample picture

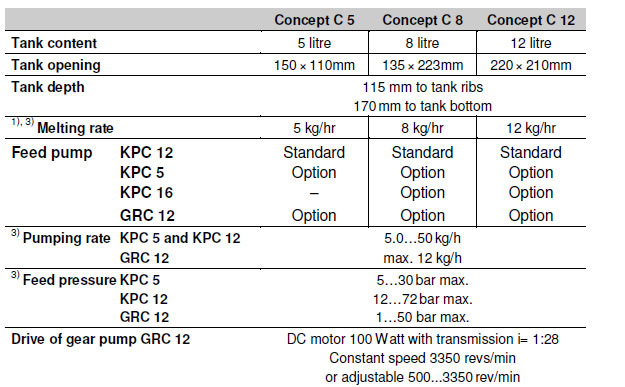

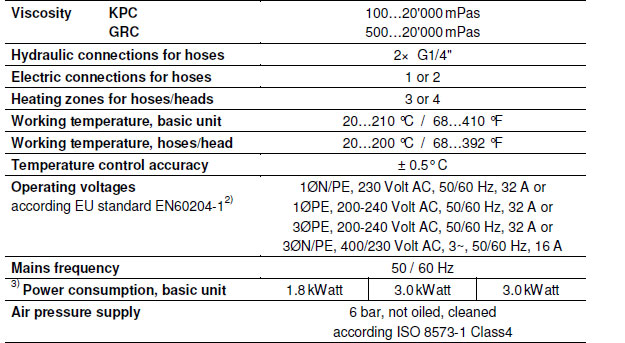

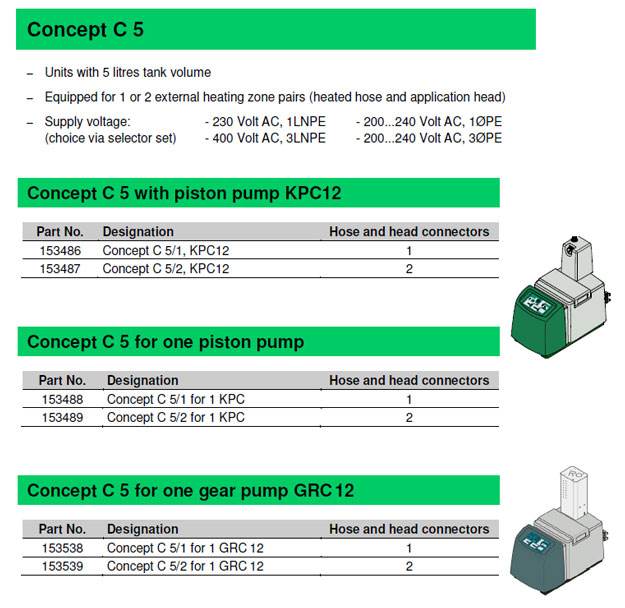

Technical Data

Weight & Dimensions

|

Type |

YL-100B |

|

Dimensions in mm |

3900mm×1100mm×1900mm (L×W×H) |

|

Weight in kg |

1500 |

Output & Speed

|

Steady production speed |

60cartons/min |

Carton and tube

|

Grammage |

Between(250-350)g/m2 |

|

|

Item |

Product size mm |

Carton Size mm |

|

I sachet into one carton |

|

90*58*20 |

Utilities

|

Standard power supply |

380V – 50Hz three phase |

|

Power consumption in KW |

1.5KW |

|

Air consumption |

20M3/h |

|

Compressed Air Pressure |

0.6MPa |

|

Noise |

<70 dB |

Functions and Options

The cartoning machine includes an automatic station to form the cartons. The carton boxes are held by vacuum

No suction carton by missing product

Product will be manually loaded on conveyer by manual ,then other things finished automaticlly.

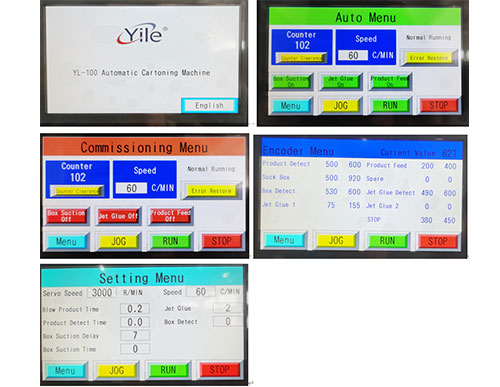

Automatically displaying device for trouble, speed and finished products counting

Machine stop running if no products or incorrect position of products. And stop automatically if incorrect position of product into carton after return or no cartons

Adopt human-machine operation system.

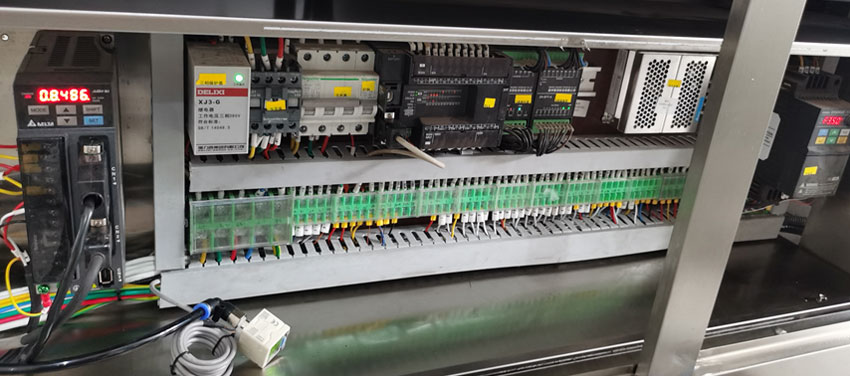

International famous brand of electric components such for PLC touch screen, frequency inverters, etc

Stable performance, operation is easy Controls

Sensors

Product presence detection sensor

Carton present detection sensor

Tructure About Every Assembly Unit

|

|

| Carton magazine which can full of 400-500pcs cartons | Pusher (which product into carton) |

|

|

| Sensor for detect product | Carton sealing |

|

|

| PLC and electrical circuit | |

|

|

| Touch screen | |

|

|

| Power supply and vacuum air supply | Touch screen |

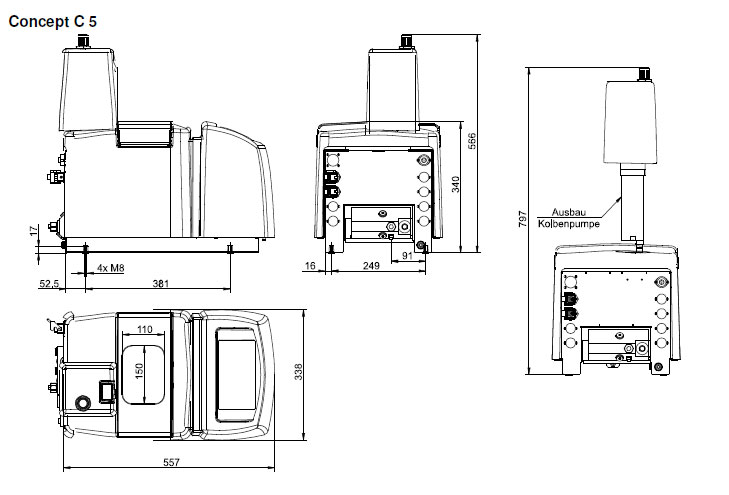

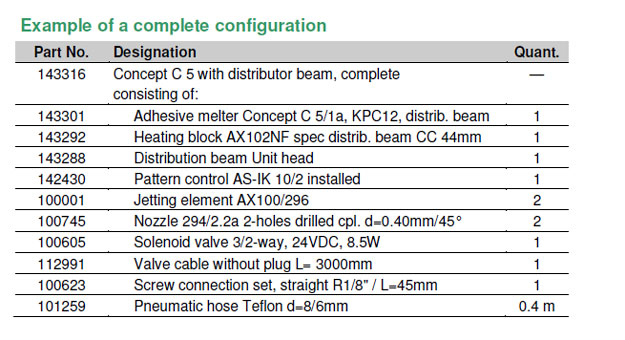

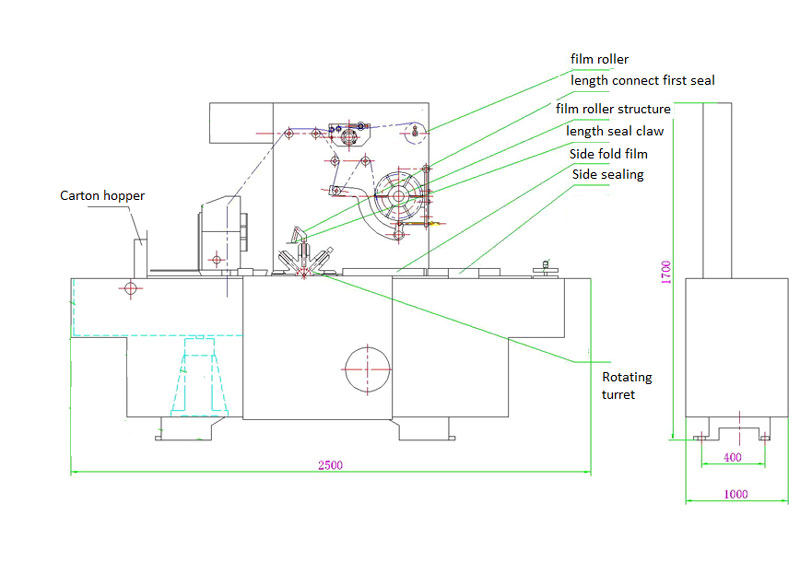

Machine Drawing Drawing

Technical Data

Instruction

Automatic Cellophane Wrapping Machine, which is mainly applied to the outside decoration packaging of square-shaped box-packaged things of such industries as medicine, food, daily chemistry, cosmetics, video products rubbers, IT etc. For example, the medical box, chewing gum, healthy products, tea-leaf, cubic sugar, condom, eraser, mosquito-repellent incense, cigarette, tape, VCD (CD)disk, poker, soap, square-shaped battery and floppy disk etc. It has the function of anti-moisture and anti-falsification, and also enhances the product level and additional value. It can combine the box-packaged machine and code-spraying machine to manufacture.

Technical Data

|

Main technical parameters |

|

|

Package material |

BOPP film and gold tear tape |

|

Speed |

60packs/min |

|

Product size mm |

90*60*20m |

|

Power of supply |

AC220V 50Hz, 6.5Kw (single phase) |

|

Weight |

600kg |

|

Power consumption in KW |

5kw |

|

Outline dimensions (Lx W x H) |

(L)3000×(W)800×(H)1500mm |

|

Control system |

Button control |

Functions and Options

1. No need to regulate the height of two work tops of the machine when the mold is replaced, no need to assemble or dismantle the material discharge chains and discharge hopper. Reduce the replacement time of the mold four hours to the present 30 minutes.

2. New-type double safeguard mechanisms are used; hence other spare parts will not be damaged when the machine runs out of step without the stop of the machine.

3. Original unilateral hand swing device to prevent from shaking the machine adversely and the non-rotation of the hand wheel during the running of the machine can secure the security of the operator.

4. New-type double-rotary film cutting cutter can ensure no need to mill the blade during many-year use of the machine, which overcomes the defect that the traditional stationary single-rotary film cutting cutter was easily worn.

On the basis of the model YL-300A, this machine is a lengthened machine for the requirement of the packaging of bulk articles required by some users. This machine features by rational structure, good-looking in excellent taste, stable run, convenient in adjustment, the added photoelectric deviation pattern rectifying register system allows the packaging of printed film packing products such as soaps and paper towel.

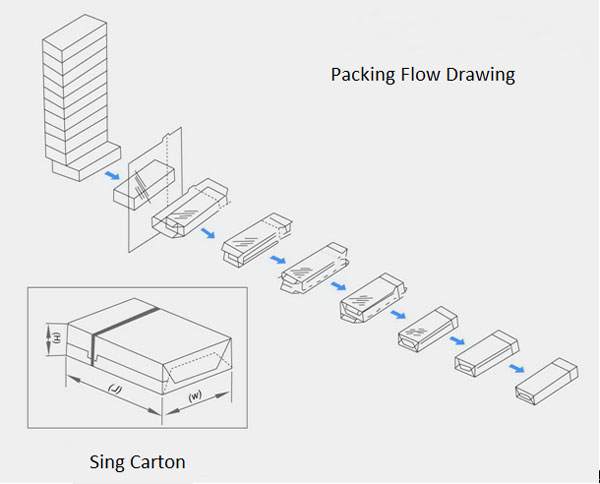

Packing Flowing Drawing

Machine Design Drawing

Yile is a cartoning machine manufacturer and supplier, factory provides you Automatic Case Packing Machine, Cartoner Machine, Box Packing Machine, Carton Packing Machine, Automatic Cartoning Machine, Food Cartoning Machine, Pharmaceutical Cartoning Machine, Case Packer Machine related knowledge, including speed, price, working principle, function, correct use Methods, and other news.

Carton boxes are indispensable in global logistics, protecting everything from groceries to electronics. ...

GET A QUOTE

+86 13566127969

If you have any questions please contact us!