If you have any questions please contact us!

Encasing Speed: 30-100 Boxes/min

Working Pressure: ≥0.6mpa

Air Consumption: 120-160L/min

Power: 220V/50Hz

Motor Power: 0.75Kw

Machine Weight: 1500Kg

inner material--loading--entering the conveyor belt--packing--unpacking--transfer box--filling (paper loading--folding paper--adding instructions)--printing batch number--sealing [insert Tongue/glue]--Packing output conveyor – finished product

YL-100 Automatic Cartoning Machine is suitable for the packaging of medicines, food, cosmetics, and daily necessities, such as blister packaging tables, blister packaging pills, four-side-sealed granules, bagged powders, plasters, lipsticks, facial masks, milk tablets, four-side-sealed wet wipes, poker... etc.

|

Encasing Speed |

30-100 Boxes/min |

|

|

Box |

Quality Requirement |

250-350g/m2 |

|

Dimension Range (L×W×H) |

(65-180)mm×(35-85)mm×(15-50)mm |

|

|

Quality Requirement |

60-70g/m2 |

|

|

Leaflet |

Unfolded Leaflet Specification (L×W) |

(80-250)mm×(90-170)mm |

|

Fold Range |

(1-4) Fold |

|

|

Compressed Air |

Working Pressure |

≥0.6mpa |

|

Air Consumption |

120-160L/min |

|

|

Power |

220V/50Hz |

|

|

Motor Power |

0.75Kw |

|

|

Machine Dimension(L×W×H) |

3100mm×1100mm×1550mm |

|

|

Machine Weight |

1500Kg |

|

|

|

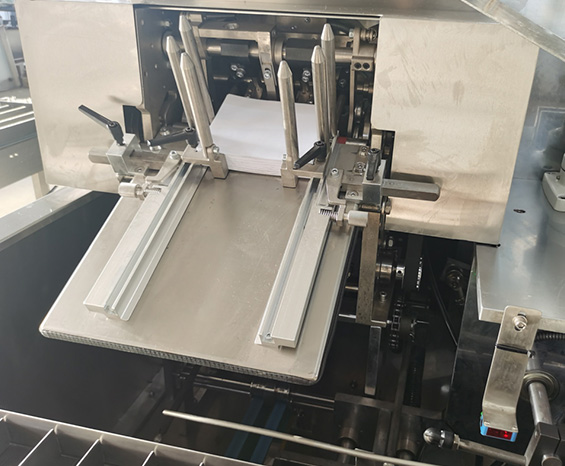

| Leaflet Folding Device | Carton magazine which can full of 400-500pcs cartons |

|

|

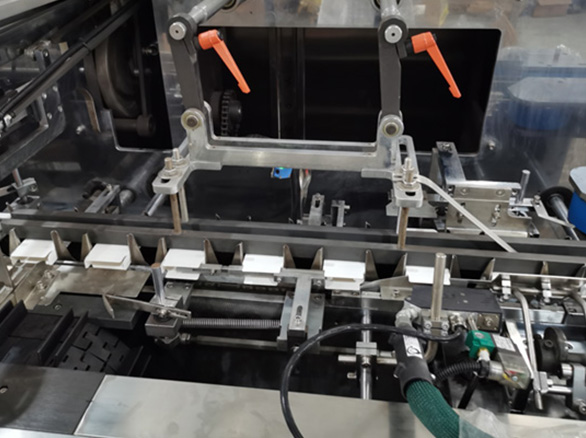

| Sensor For Detect Product | Carton Sealing |

【1】Automatic display of packing speed and counting.

【2】Automatic cartoning machine is not necessary to change the mold when changing the specifications, only need to adjust;

【3】 It adopts automatic feeding, unpacking, feeding, sealing, and output. Compared with other packaging forms, it has a compact and reasonable structure, and is easy to operate and adjust;

【4】Servo/stepping motor, touch screen and PLC programming control system are adopted to make the display and operation of the man-machine interface more clear and convenient, with a high degree of automation and more humanization;

【5】Wide range of packaging, easy adjustment, quick conversion between various specifications and sizes;

【6】Various automatic food and box packing systems can be designed according to the requirements of packaging materials.

【7】According to customer requirements, the hot melt adhesive machine can be equipped with a hot melt adhesive spray seal box.

【8】According to customer requirements, flip-type safety cover is adopted, which is easy to operate and beautiful in appearance.

【9】The photoelectric eye automatic detection and tracking system is adopted, and there is no product without the suction box, which saves packaging materials to the greatest extent;

【10】When there is no product or the product is not in place, the machine will idle without pushing the product. When the product is restored, it will automatically run. When the product is in the box, it will automatically stop and the main device will drive the motor to protect against overload.

【11】Automatic cartoning machine can be linked with aluminum-plastic packaging machines, pillow packaging machines, three-dimensional packaging machines, filling lines, filling machines, labeling machines, inkjet printers, online laminating machines, and other production lines to achieve linked production.

Yile is a cartoning machine manufacturer and supplier, factory provides you Automatic Case Packing Machine, Cartoner Machine, Box Packing Machine, Carton Packing Machine, Automatic Cartoning Machine, Food Cartoning Machine, Pharmaceutical Cartoning Machine, Case Packer Machine related knowledge, including speed, price, working principle, function, correct use Methods, and other news.

Carton boxes are indispensable in global logistics, protecting everything from groceries to electronics. ...

GET A QUOTE

+86 13566127969

If you have any questions please contact us!